Behaviors of Silicone Adhesives to Various Types of Glass in Facade System

![]()

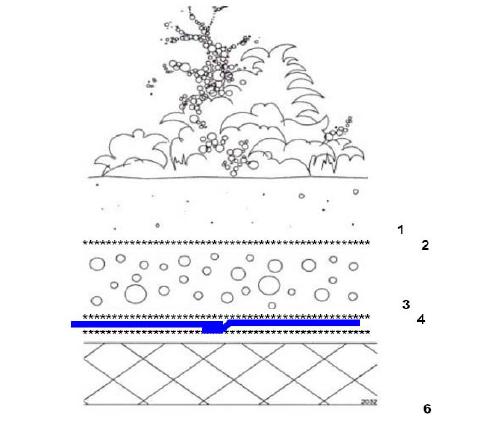

1. Uncoated Float Glass

Float glass is generally suitable for all bonded glass facades. To reduce the risk of damage from glass breakage, use tempered or laminated glass (with polyvinyl butyral film, PVB or cast resins). Silicone adhesives ensure excellent adhesion to tempered glass without additional tests. Where laminated glass is used, it is recommend carrying out compatibility tests.

2. Pyrolytic Coatings for reflective Glass (hard Coatings)

Coated glass optimizes the thermal insulation of the facade while providing a particularly attractive optical effect. Pyrolytic coatings (hard coatings) of metal oxides are ideal for structural glazing, since they resist environmental conditions. For silicone adhesives, it is warrantied for adhesion after individual adhesion tests are conducted.

3. Ceramic Coatings

Ceramic coatings are used predominantly in the spandrel area. At the edge regions of the glass, they cover color differences within the insulating glazing edge seal and between the edge seal and the structural glazing adhesive. The adhesive strength of silicone adhesives has been proven in numerous projects and tests according to the European guideline for bonded glass structures (EOTA ETAG No. 002). However, since the composition of the coatings may vary greatly, the warranty requires that individual tests be carried out for each project.

4. Magnetron Coatings for lowE Glass (soft Coatings)

These coatings contain precious metals (such as silver) and are generally not resistant enough for use in structural glazing bonds. If necessary, strip off the coating around the bond. Adhesion should therefore be tested on the abraded specimens, since abrasion represents a modification of the surface, and is subject to various parameters. Always observe the glass manufacturer’s instructions.